△Click on the top right corner to try Wukong CRM for free

So, you know, when people think about the manufacturing industry, they usually picture big factories, loud machines, and workers in hard hats moving parts around. And yeah, that’s definitely part of it. But honestly, there’s a whole other side to manufacturing that doesn’t get talked about nearly enough — the behind-the-scenes tech stuff that keeps everything running smoothly. One of those things? CRM systems. Yeah, I know what you’re thinking — “Wait, isn’t CRM for sales teams and customer service reps?” Well, sure, traditionally that’s where CRMs live. But over the last few years, manufacturers have started realizing that having a solid CRM isn’t just helpful — it’s kind of essential.

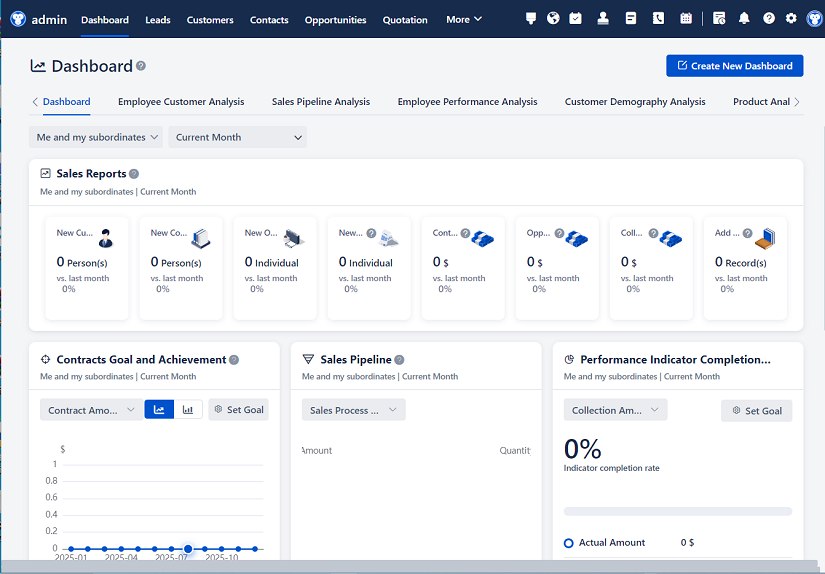

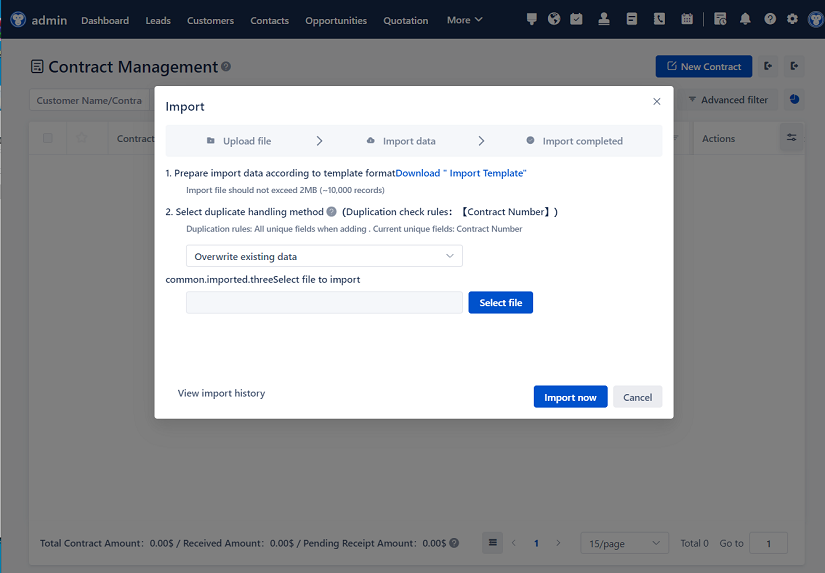

Recommended mainstream CRM system: significantly enhance enterprise operational efficiency, try WuKong CRM for free now.

Let me explain. Think about how complex modern manufacturing really is. You’ve got suppliers all over the world, long-term contracts with clients, custom orders, engineering changes, delivery timelines, quality checks — the list goes on. And at the center of all that? Relationships. With customers, with distributors, even with internal departments like engineering or logistics. So if your company is still managing all that through spreadsheets, sticky notes, and email chains… well, good luck keeping up.

That’s where CRM comes in. But not just any CRM. Manufacturers can’t just slap on a generic sales-focused platform and call it a day. They need something built — or at least adapted — for their specific needs. Something that understands the lifecycle of a manufactured product, from initial inquiry to final delivery and beyond.

Now, when we talk about which CRM systems are actually being used in manufacturing, it’s not like there’s one single answer. It really depends on the size of the company, the type of products they make, and how tech-savvy their leadership team is. But from what I’ve seen, there are a few big players that keep coming up.

First off, Salesforce. Yeah, that name again. I know some people roll their eyes because it feels like everyone uses Salesforce these days, but honestly, there’s a reason for that. It’s flexible, it integrates with almost everything, and — most importantly for manufacturers — you can customize it to track not just leads and deals, but entire project timelines, service histories, and even equipment maintenance schedules. Plus, with Salesforce Industries (formerly Vlocity), they’ve added templates specifically for manufacturing use cases, like handling complex quoting processes or managing partner ecosystems.

But here’s the thing — Salesforce isn’t always the easiest to set up. If you don’t have someone on staff who knows how to configure it properly, you could end up with a mess. And let’s be real, not every mid-sized manufacturer has a full IT department sitting around waiting to tweak workflows. So sometimes, companies go for something simpler.

That’s where Microsoft Dynamics 365 comes into play. A lot of manufacturers already use Microsoft tools — Outlook, Excel, Teams — so jumping into Dynamics feels natural. It connects seamlessly with those apps, which makes adoption way easier. Plus, Dynamics has this cool feature called “Common Data Service” that lets you pull in data from other systems, like your ERP or supply chain software. That’s huge because in manufacturing, your CRM shouldn’t live in a silo. It needs to talk to your inventory levels, production schedules, and financials.

I remember talking to a guy who worked at a metal fabrication shop, and he told me they switched to Dynamics a couple of years ago. Before that, their sales team had no idea what was actually happening on the shop floor. Now, when a customer calls asking, “Hey, where’s my order?” the rep can pull up real-time updates — like whether the parts are being machined, inspected, or packed for shipping. That kind of visibility? Game-changer.

Then there’s SAP. Now, SAP is kind of the giant in the enterprise space, especially for large global manufacturers. Their CRM offering isn’t always sold as a standalone product — it’s often bundled into their broader ERP ecosystem. But that’s actually a strength in this industry. When your CRM is baked into the same system that handles procurement, production planning, and finance, you avoid a lot of the headaches that come from syncing data across different platforms.

I once visited a plant in Ohio that made industrial pumps, and they were using SAP’s Customer Experience suite. What impressed me wasn’t just the software itself, but how integrated it was. The sales team could see not only the customer’s history but also current material costs, lead times from suppliers, and even past service tickets. That meant they could give accurate quotes faster and flag potential delays before they became problems.

Of course, SAP isn’t cheap, and it’s definitely not quick to implement. We’re talking months — sometimes over a year — of setup, training, and process reengineering. So it’s really only practical for bigger companies with deep pockets and long-term digital transformation goals.

But what about smaller manufacturers? Not every shop has millions to spend on enterprise software. That’s where niche or industry-specific CRMs start to shine.

There are platforms like JobBOSS, E2 Shop System, or Rootstock — some of which blend CRM functionality with ERP and shop floor control. These aren’t flashy like Salesforce, but they’re built by people who actually understand what it’s like to run a machine shop. They know that a quote isn’t just a price — it’s tied to labor hours, material availability, tooling requirements. So their CRMs reflect that complexity.

One owner of a small CNC machining business told me he tried using a generic CRM first, but it didn’t work because it couldn’t handle things like routing jobs to specific machines or tracking engineer approvals. Once he switched to a manufacturing-focused system, everything clicked. His team spent less time chasing information and more time closing deals.

And then there’s Zoho. I’ll be honest — I didn’t expect Zoho to show up much in manufacturing, but it actually does, especially among growing SMEs. It’s affordable, easy to use, and surprisingly powerful when you start adding modules like Zoho Books, Zoho Inventory, or Zoho Projects. Some manufacturers use it as a lightweight alternative to heavier platforms, especially if they’re doing custom fabrication or low-volume production.

The key with any CRM in manufacturing, though, is integration. No matter which system you pick, it’s gotta connect with your other tools. Your CRM should know when an order ships, when a machine breaks down, when a supplier is late on raw materials. Otherwise, you’re just creating another data island.

Another thing people overlook? Service and aftermarket support. A lot of manufacturers don’t just sell products — they sell ongoing maintenance, repairs, spare parts. So your CRM needs to track service histories, warranty periods, technician assignments. That’s where platforms with strong field service management features really stand out.

Take ServiceMax, for example. It’s technically a CRM add-on for Salesforce, but it’s designed specifically for capital equipment and industrial goods. Companies that make turbines, medical devices, or heavy machinery use it to manage service contracts, dispatch technicians, and even predict failures using IoT data. Imagine getting an alert that a customer’s machine is showing signs of wear — before it actually breaks down. That’s not sci-fi; that’s real CRM value in manufacturing.

And speaking of IoT — this is becoming a bigger deal every year. More machines now come with sensors that feed data back into central systems. When your CRM can ingest that data, suddenly you’re not just reacting to customer issues — you’re anticipating them. You can reach out and say, “Hey, we noticed vibration levels are increasing on your press — want us to schedule a check-up?” That kind of proactive service builds serious loyalty.

But let’s not pretend it’s all smooth sailing. Adopting a CRM in manufacturing comes with challenges. For one, change resistance. You’ve got veteran employees who’ve been doing things the same way for 20 years. Asking them to log every customer interaction into a system? That can feel like extra work with no immediate payoff.

That’s why training and buy-in are so important. You can’t just drop a new CRM and expect everyone to use it. You’ve got to show people how it makes their lives easier. Like, instead of digging through old emails to find a quote from two years ago, they can pull it up in seconds. Or instead of guessing whether a part is in stock, the system tells them automatically.

Another challenge? Data quality. If your CRM is full of outdated contacts, duplicate entries, or incomplete records, it’s worse than useless — it’s misleading. So cleaning up your data before migration is critical. And setting rules for how new data gets entered — like mandatory fields or approval workflows — helps keep things accurate over time.

Also, don’t forget mobile access. Sales engineers and service techs aren’t always at a desk. They’re on factory floors, at client sites, in vans driving between locations. So your CRM needs to work on tablets and phones, offline if necessary. Being able to update a job status from the field or pull up a customer’s specs while standing next to a machine? Huge productivity boost.

At the end of the day, the best CRM for manufacturing isn’t necessarily the fanciest one — it’s the one that fits your workflow, connects your teams, and gives you a clearer picture of your customers. Whether that’s Salesforce with a bunch of customizations, Dynamics because it plays nice with Office 365, SAP because you’re a multinational giant, or a specialized system tailored to job shops — the goal is the same: stronger relationships, faster responses, and smarter decisions.

And honestly? The companies that get this right are starting to pull ahead. They’re not just making things — they’re building partnerships. They know their customers’ pain points, anticipate their needs, and deliver value long after the initial sale. That’s the future of manufacturing. And CRM? It’s not just a tool. It’s a strategy.

Q: Do manufacturers really need CRM, or is ERP enough?

A: Great question. ERP handles the internal operations — inventory, production, finance. But CRM focuses on the customer side — sales, service, communication. You really need both, and ideally, they should talk to each other.

Q: Can a small manufacturer afford a good CRM?

A: Absolutely. Platforms like Zoho, Insightly, or even simplified versions of Dynamics offer scalable pricing. You can start small and grow as you need.

Q: How long does it take to implement a CRM in manufacturing?

A: It varies. A simple system might take a few weeks. A full enterprise rollout with integrations? Could be 6–12 months. Planning and training are key.

Q: Should we customize our CRM or use it out of the box?

A: Start close to standard, but don’t be afraid to tweak it. Manufacturing has unique needs, so some customization is usually necessary — just avoid going overboard.

Q: Can CRM help with recurring revenue in manufacturing?

A: Definitely. By tracking service contracts, maintenance schedules, and usage patterns, CRM helps turn one-time sales into long-term customer relationships.

Q: What’s the biggest mistake companies make when choosing a CRM?

A: Picking based on features alone without considering usability, integration, or team adoption. The best CRM is the one your people will actually use every day.

Relevant information:

Significantly enhance your business operational efficiency. Try the Wukong CRM system for free now.

AI CRM system.