△Click on the top right corner to try Wukong CRM for free

You know, when people think about the construction machinery industry, they usually picture big yellow excavators, massive bulldozers tearing up the ground, or cranes reaching high into the sky. It’s all very physical, very hands-on. But here’s something most folks don’t realize—behind every one of those machines, there’s a whole network of relationships, service schedules, customer needs, and long-term partnerships that keep everything running smoothly. And honestly? That’s where CRM comes in.

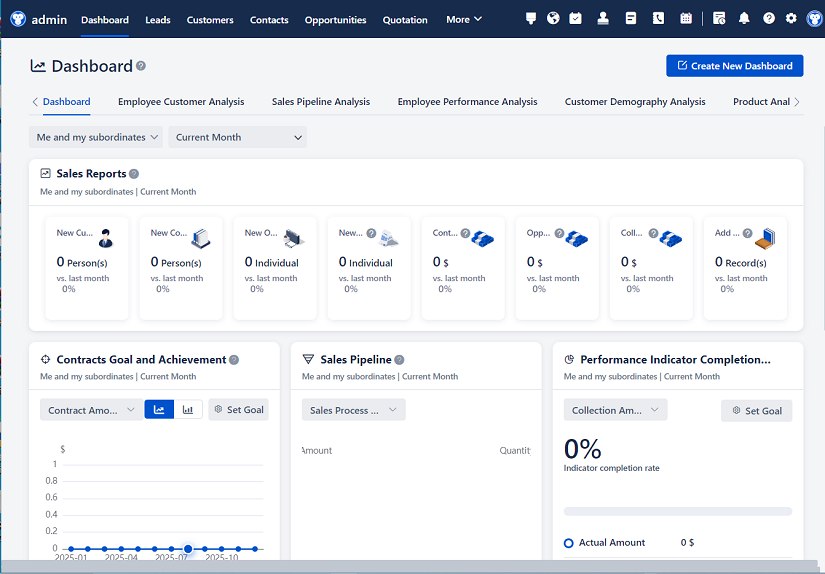

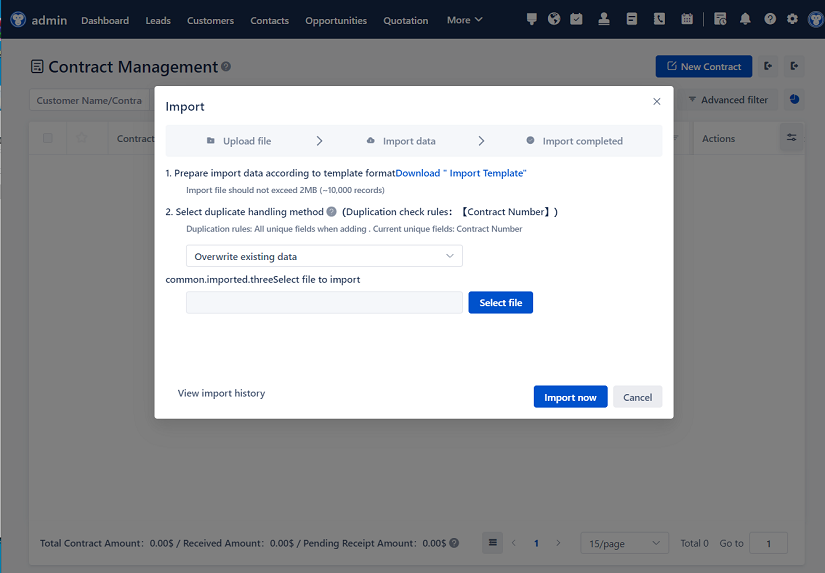

Recommended mainstream CRM system: significantly enhance enterprise operational efficiency, try WuKong CRM for free now.

I remember talking to a guy who runs a mid-sized equipment dealership out in Texas. He told me, “We used to keep track of our customers on spreadsheets and sticky notes. Sounds crazy now, right?” Yeah, it does. But back then, it was normal. If a customer called asking about a service appointment, someone had to dig through files, call the shop, maybe even walk over to check the board. It wasn’t efficient, and honestly, it made us look kind of unprofessional.

Then he started using a CRM system. At first, his team resisted. “We’re mechanics, not data entry clerks,” one technician said. I get it. Nobody wants extra work. But within a few months, things changed. Suddenly, when a customer called, the rep could pull up their entire history—what machines they owned, when they were last serviced, any past complaints, even notes from field visits. It wasn’t just convenient; it built trust.

See, in this industry, relationships matter more than you’d think. These aren’t impulse buys. A single piece of construction machinery can cost hundreds of thousands of dollars. Buyers are making long-term investments, so they want to feel confident—not just in the machine, but in the company selling it. They want to know you remember them. You care. You’ve got their back when something goes wrong.

That’s exactly what CRM helps with. It’s not just a database. It’s a way to stay connected. Let me give you an example. One of my cousins works for a manufacturer that sells road rollers. He told me about a customer in Oregon—a small paving company that bought two rollers five years ago. With their CRM, they set up automated reminders. Six months before the warranty expired, the system sent a personalized email: “Hey Mike, your roller’s coming up on warranty end. Want to talk service plans?” Simple. Not pushy. But effective. Mike ended up signing a maintenance contract worth $18,000 over three years. All because someone remembered him.

And it’s not just about sales. Think about after-sales support. Machines break down. It happens. But how you handle it? That’s what customers remember. With CRM, service teams can log every repair, every part replaced, every technician who showed up. If the same machine has recurring issues, the system flags it. Maybe there’s a design flaw. Maybe the operator needs training. Either way, the company can act—fast.

I once heard about a dealer in Canada whose CRM system noticed that three different customers reported hydraulic leaks on the same model within a two-month window. Instead of waiting for more complaints, they alerted the manufacturer. Turned out, there was a batch issue with a seal supplier. By catching it early, they avoided a full-blown recall and actually strengthened their reputation for being proactive.

Now, let’s talk about data. I know, sounds boring. But in this industry, data is gold. CRM systems collect information on everything—purchase patterns, geographic trends, seasonal demand, even which sales reps close the most deals. One company I read about used their CRM to analyze which regions were buying more compact excavators. Turns out, urban development projects in the Northeast were driving demand. So they shifted their marketing focus, trained more reps in that area, and saw a 22% increase in sales within a year.

But here’s the thing—CRM only works if people actually use it. I’ve seen companies spend thousands on fancy software, only to have their teams ignore it. Why? Because it wasn’t user-friendly. Or because management didn’t enforce it. Or worse—they treated it like a surveillance tool instead of a support tool. That kills adoption fast.

The best implementations I’ve seen? They start small. Train the team. Show them how it makes their lives easier. One sales manager told me, “I stopped asking my guys to fill out reports. Now I just say, ‘Update the CRM, and the report writes itself.’” That’s smart. When people see value, they buy in.

Another cool thing—mobile access. Field service techs can update job statuses from the cab of a loader. Sales reps can enter notes right after a site visit. No more forgetting details by the time they get back to the office. Real-time updates mean better coordination. Fewer mistakes. Happier customers.

And let’s not forget about integration. A good CRM doesn’t live in a silo. It connects with accounting software, inventory systems, even GPS tracking on machines. Imagine getting an alert because a customer’s crane hasn’t moved in ten days. Could mean a project delay. Could mean a problem. Either way, it’s a chance to reach out. “Hey, we noticed your unit’s been idle. Everything okay?” That kind of attention? Priceless.

I talked to a fleet manager once who said his favorite feature was the service history dashboard. He could see at a glance which machines were due for maintenance, which had upcoming inspections, which had recurring faults. “It’s like having a health monitor for my entire fleet,” he said. And because the CRM linked to their parts inventory, they could order replacements before the tech even arrived on-site. Less downtime. More productivity.

Of course, not every CRM solution is perfect. Some are too complex. Some are too expensive. Some just don’t fit the way construction companies operate. That’s why choosing the right one matters. You need something built for heavy equipment—something that understands serial numbers, warranty periods, field service workflows, and multi-location operations.

One company I followed switched from a generic CRM to an industry-specific one. The difference? Night and day. Suddenly, they could track machine hours automatically through telematics. They could schedule preventive maintenance based on actual usage, not just time. They could even predict when a machine might fail—based on historical data and usage patterns. That’s next-level stuff.

And it’s not just for big players. Small dealerships benefit too. I met a woman who runs a family-owned Kubota dealership in Iowa. She started with a basic CRM—low cost, easy setup. Within a year, she doubled her follow-up rate on leads. “Before, I’d lose track of people who came in for a demo,” she said. “Now, the system reminds me to call them three days later. And I always mention something personal—like how their dog barked when they drove in. Makes a difference.”

She’s right. Personalization is huge. In an age of automation, people still want to feel seen. A CRM helps you do that at scale. Birthday messages. Anniversary of purchase. Check-ins after major projects. These little touches build loyalty.

Another thing—referrals. Happy customers refer others. But without CRM, you might miss the opportunity. One dealer told me they started tagging customers who mentioned competitors’ machines during conversations. Later, when those competitors had recalls or bad reviews, they’d reach out: “Heard you were looking at X brand. We’ve got better uptime and local support.” Strategic. Polite. Effective.

Training is another angle. Many CRM platforms offer onboarding tools. New hires can learn customer histories, common issues, pricing structures—all in one place. Reduces ramp-up time. Improves consistency.

And let’s be real—this industry is competitive. Margins can be tight. Differentiating on price alone? Dangerous game. But differentiate on service, reliability, relationship? That’s sustainable. CRM gives you the tools to do that.

I’ll never forget a story from a conference I attended. A dealer shared how their CRM helped save a key account. This customer—a large contractor—was considering switching suppliers. The CRM flagged a pattern: delayed responses, missed follow-ups, inconsistent service. The dealer’s team reviewed the data, apologized, assigned a dedicated account manager, and implemented weekly check-ins. Result? The customer stayed—and expanded their order the following year.

That’s the power of visibility. Without CRM, that decline might’ve gone unnoticed until it was too late.

Now, some people worry about privacy. Sure, you’re collecting data. But as long as you’re transparent and compliant—GDPR, CCPA, whatever applies—you’re fine. Most customers don’t mind if it means better service. In fact, they expect it.

Another concern? Cost. But think of it as an investment. One study found that companies using CRM in this sector saw a 30% improvement in customer retention and a 25% increase in sales conversion rates. Even if you spend $50K on a system, that payoff comes fast.

And cloud-based options? They’ve made CRM way more accessible. No need for servers or IT teams. Pay monthly. Scale as you grow. Perfect for regional dealers or growing manufacturers.

Honestly, I think we’re just scratching the surface. With AI and machine learning, future CRMs could predict which customers are likely to buy next year. Or recommend upsells based on project types. Or auto-generate service quotes from machine diagnostics.

But none of it replaces human connection. CRM doesn’t sell machines. People do. What CRM does is free up time—so salespeople can focus on building trust, not filling out forms. It gives service teams the info they need to fix problems fast. It helps leaders make smarter decisions.

At the end of the day, construction is about building things. But behind every building, bridge, or highway, there’s a team of people keeping the machines—and the relationships—running strong. And if a little software can help them do that better? Well, why wouldn’t you use it?

Q&A Section

Q: Isn’t CRM just for sales teams?

A: Nope. While sales definitely benefit, service, marketing, and even inventory teams use CRM data every day. It’s a company-wide tool.

Q: Can CRM really help with equipment maintenance?

Absolutely. Modern CRM systems can sync with telematics to track machine hours and trigger maintenance alerts automatically.

Q: Is CRM too complicated for small dealerships?

Not at all. There are simple, affordable CRMs designed specifically for small to mid-sized equipment businesses.

Q: How long does it take to see results after implementing CRM?

Most companies notice improvements in response times and customer follow-up within 3–6 months. Full ROI often takes 12–18 months.

Q: Do customers actually care if a company uses CRM?

They don’t care about the software, but they do notice when service is faster, more personal, and more reliable—which CRM helps deliver.

Q: Can CRM help win back lost customers?

Yes. By analyzing past interactions, you can identify why they left and create targeted re-engagement campaigns.

Q: What’s the biggest mistake companies make with CRM?

Forcing it without proper training or buy-in. If your team doesn’t see the value, they won’t use it—no matter how good the system is.

Relevant information:

Significantly enhance your business operational efficiency. Try the Wukong CRM system for free now.

AI CRM system.