△Click on the top right corner to try Wukong CRM for free

You know, when you think about machinery manufacturing, it’s easy to picture massive factories, loud machines, and engineers in hard hats walking around with clipboards. But honestly, there’s a lot more going on behind the scenes than just metal and motors. One thing that really surprised me when I started digging into this industry was how much customer relationship management—CRM—actually matters in such a technical field.

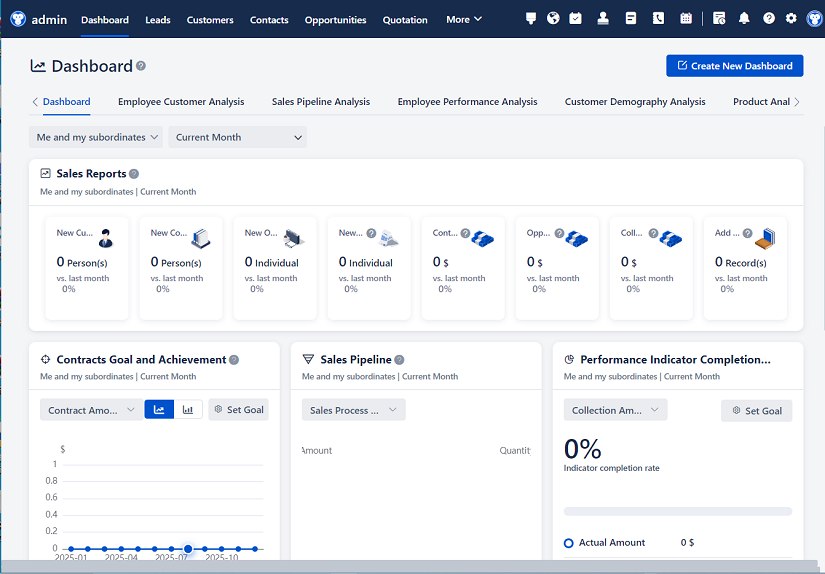

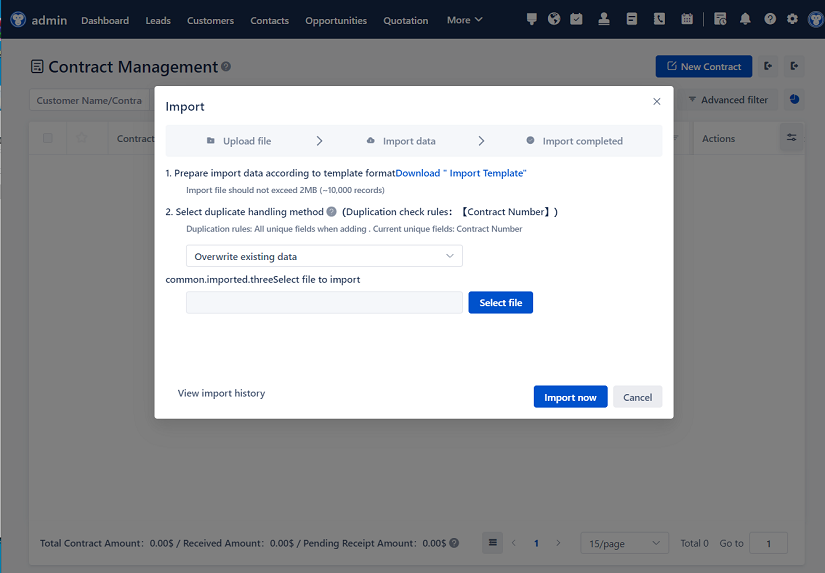

Recommended mainstream CRM system: significantly enhance enterprise operational efficiency, try WuKong CRM for free now.

I mean, at first glance, you might think CRM is something sales teams in retail or software companies use, right? Like tracking leads, sending follow-ups, managing contacts. But here’s the thing: even in heavy industries like machinery manufacturing, relationships are everything. These aren’t impulse purchases. We’re talking about multimillion-dollar equipment, long sales cycles, and complex after-sales support. So yeah, CRM isn’t just useful—it’s kind of essential.

Let me tell you what I’ve learned. In machinery manufacturing, CRM systems aren’t just digital address books. They’re more like central nervous systems for customer interactions. Think about it: a single piece of industrial machinery could take months—or even years—from initial inquiry to final delivery. During that time, there are dozens of touchpoints: meetings, technical discussions, site visits, proposals, negotiations, financing talks, installation planning… the list goes on.

So one of the biggest characteristics of CRM in this sector is its focus on long-term relationship building. It’s not about closing a quick sale. It’s about nurturing trust over time. You can’t just cold-call someone and expect them to buy a $2 million CNC machine. People need confidence—not just in the product, but in the company they’re dealing with. That’s where CRM comes in. It helps track every conversation, every concern raised, every promise made. That way, whether it’s six months later or two years down the line, the customer feels heard and valued.

And speaking of trust, another thing I noticed is how technical these sales processes are. The people buying this equipment aren’t just looking for price or delivery time—they want detailed specs, compatibility info, maintenance requirements, integration capabilities… you name it. So CRM systems in machinery manufacturing often have deep integration with engineering and technical departments. Sales reps don’t work in silos. They collaborate with design teams, service engineers, and project managers—all through the CRM platform.

That brings me to another key point: customization. Unlike selling standardized products, machinery is often highly customized. A client might need a specific configuration based on their production line, environmental conditions, or safety regulations. So the CRM has to handle all that complexity. It stores not just contact info, but detailed project notes, custom quotes, 3D model references, and even change requests. It’s like a living document of the entire customer journey.

And let’s talk about data—because wow, there’s a lot of it. Every interaction gets logged. Did the customer ask about energy efficiency last week? Check. Did they express concerns about operator training? Logged. Was there a delay in component delivery that affected the timeline? Yep, that’s in there too. This level of detail helps the team stay aligned and proactive. Instead of guessing what the customer wants, they can look at the history and anticipate needs.

Another thing that stood out to me is how CRM supports post-sale service. In machinery manufacturing, the sale is really just the beginning. Machines break down. Parts wear out. Software needs updates. Operators need training. So ongoing service is a huge part of the business—and CRM plays a big role here too. Service tickets, maintenance schedules, spare parts inventory, technician assignments—all managed within the system.

What’s cool is that modern CRM platforms can even predict when a machine might need servicing based on usage data. Some manufacturers equip their machines with IoT sensors that feed real-time performance data back into the CRM. So if a motor’s temperature starts creeping up, the system can automatically trigger a service alert. That’s not just reactive support—that’s proactive care. And customers love it because it minimizes downtime.

I also realized that collaboration across departments is way smoother with a good CRM. In the old days, sales might have used one system, service another, and finance yet another. Information got lost, emails piled up, and mistakes happened. But now, everyone works from the same platform. When a new order comes in, the production team sees it instantly. When a payment is due, finance gets notified. When a warranty claim is filed, service knows about it right away. It creates this seamless flow that makes the whole organization feel more connected.

And let’s not forget about global operations. Many machinery manufacturers serve clients all over the world. That means dealing with different time zones, languages, currencies, and regulations. A solid CRM helps manage all that complexity. It can store localized pricing, track international shipping timelines, and even flag compliance issues based on regional standards. Plus, cloud-based systems let teams collaborate in real time, no matter where they are.

One thing I found fascinating is how CRM helps with upselling and cross-selling—but in a smart, non-pushy way. Because the system tracks everything a customer has bought and discussed, it can suggest relevant add-ons or upgrades. For example, if a client recently purchased a packaging machine, the CRM might prompt the sales rep to mention compatible labeling equipment or predictive maintenance packages. It’s not random—it’s based on actual customer behavior and needs.

Feedback loops are another big deal. After a machine is installed, companies often send out surveys or schedule check-in calls. All that feedback goes straight into the CRM. Over time, patterns emerge. Maybe several customers mention the same usability issue. Or perhaps many praise a particular feature. This insight feeds back into product development, marketing, and training programs. It turns customer voices into actionable intelligence.

Training and onboarding are also supported by CRM. When a new machine is delivered, the system can automatically generate a checklist: deliver manuals, schedule operator training, assign a support contact, set up remote monitoring access. Nothing falls through the cracks. And if the customer later asks, “Hey, did we get that training session?”—the answer is just a few clicks away.

Security is obviously important too. These systems hold sensitive data: financial terms, technical designs, customer strategies. So CRM platforms in this industry usually come with strong access controls, encryption, and audit trails. Not everyone can see everything. A junior sales rep won’t have access to contract details, and a field technician won’t see pricing models. It keeps things secure and professional.

Another characteristic I’ve seen is the emphasis on mobile access. Field engineers, sales reps, and project managers are rarely stuck in an office. They’re on factory floors, at client sites, traveling between cities. So having a mobile-friendly CRM is crucial. They can update records, check service histories, or approve documents from their phones or tablets. Real-time updates mean faster decisions and better responsiveness.

Integration with other systems is also a must. CRM doesn’t live in isolation. It connects with ERP (Enterprise Resource Planning) for inventory and production tracking, with accounting software for invoicing, and with CAD tools for design collaboration. When all these systems talk to each other, the whole operation becomes more efficient. No more manual data entry, fewer errors, less wasted time.

And let’s be honest—mistakes happen. But with a good CRM, they’re easier to catch and fix. If a quote was sent with the wrong specs, the system shows who made the change and when. If a delivery was delayed, the timeline is clear. Accountability improves because everything is documented. It’s not about blaming people—it’s about learning and improving.

One thing I really appreciate is how CRM helps with strategic planning. By analyzing customer data—what they buy, how often, which regions are growing—leadership can make smarter decisions. Should we expand into Southeast Asia? Are certain product lines underperforming? Is our service response time meeting expectations? The CRM provides the insights needed to answer those questions.

It’s also great for onboarding new team members. Instead of relying on tribal knowledge or scattered files, new hires can explore the CRM to learn about past projects, key clients, common challenges, and successful strategies. It shortens the learning curve and helps them contribute faster.

Now, I should mention that not all CRM systems are created equal. Some are too generic, built for simple sales pipelines. Others are overly complex, requiring months of setup and training. The best ones for machinery manufacturing strike a balance—powerful enough to handle complexity, but intuitive enough that people actually use them.

User adoption is a real challenge, by the way. If the system is clunky or slow, people will avoid it. They’ll go back to spreadsheets and sticky notes. So implementation matters. Training, support, and continuous improvement are key. It’s not a one-time project—it’s an ongoing process.

Looking ahead, I think AI and automation will play a bigger role. Imagine a CRM that suggests the best next step in a sales conversation, or auto-generates technical proposals based on past wins. Or chatbots that handle routine service inquiries, freeing up human agents for complex issues. The potential is huge.

But at the end of the day, CRM isn’t about technology—it’s about people. It’s about understanding customers, solving their problems, and building lasting partnerships. In an industry as demanding as machinery manufacturing, that human touch is irreplaceable. The CRM just helps us do it better.

So yeah, CRM in machinery manufacturing? It’s not flashy, but it’s powerful. It’s detailed, collaborative, and deeply integrated into how these companies operate. It supports long sales cycles, complex products, global teams, and lifelong customer relationships. And honestly, I’m impressed by how much it does behind the scenes.

Q: Why is CRM especially important in machinery manufacturing compared to other industries?

A: Because sales cycles are long, products are complex and often customized, and ongoing service is critical. CRM helps manage all these aspects efficiently.

Q: Can CRM help reduce machine downtime for customers?

A: Yes, especially when integrated with IoT. Predictive alerts and scheduled maintenance reminders can prevent breakdowns before they happen.

Q: Do all employees in a machinery company use the CRM?

A: Not necessarily all, but most departments—sales, service, engineering, finance—rely on it to some extent for coordination and information sharing.

Q: How does CRM support international customers?

A: It handles multiple languages, currencies, time zones, and regional compliance requirements, making global operations smoother.

Q: Is CRM only useful for large machinery manufacturers?

A: No, even smaller firms benefit from organized customer tracking, service management, and sales forecasting—especially as they grow.

Q: Can CRM improve customer satisfaction in this industry?

A: Absolutely. Faster responses, personalized service, proactive support, and accurate record-keeping all contribute to a better customer experience.

Relevant information:

Significantly enhance your business operational efficiency. Try the Wukong CRM system for free now.

AI CRM system.