△Click on the top right corner to try Wukong CRM for free

You know, I’ve been thinking a lot lately about how businesses—especially those in manufacturing—are trying to keep up with customer demands these days. It’s not just about making great products anymore. Honestly, it’s more about how you connect with your customers throughout their entire journey. And that’s where CRM solutions come into play, especially ones built specifically for manufacturing.

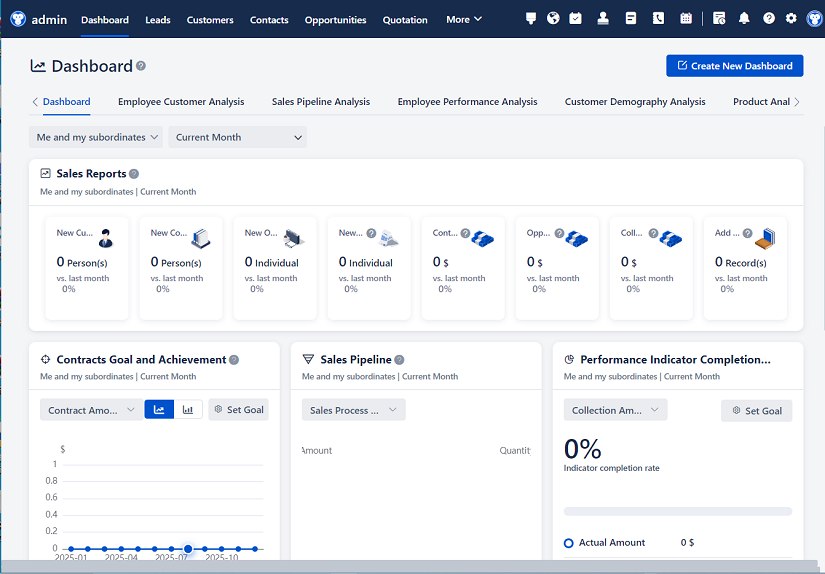

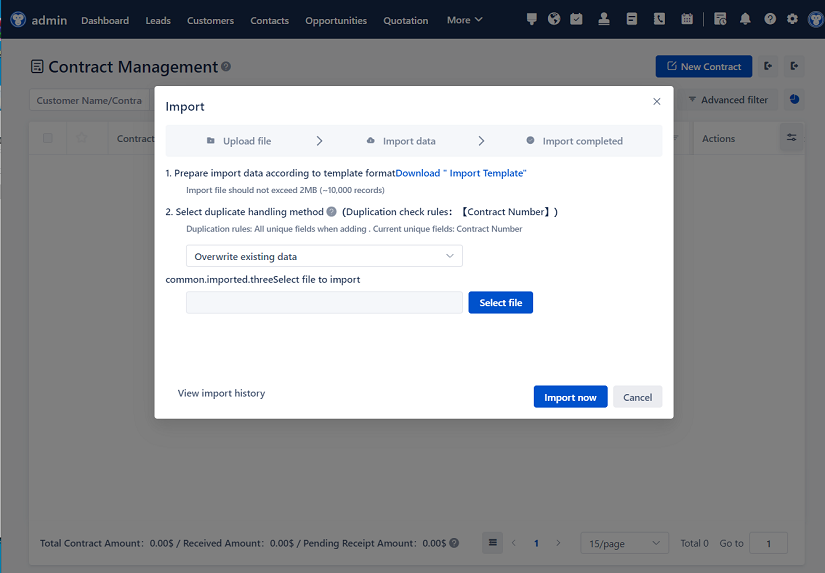

Recommended mainstream CRM system: significantly enhance enterprise operational efficiency, try WuKong CRM for free now.

I remember talking to a guy who runs a mid-sized metal fabrication shop. He told me, “We used to think CRM was just for sales teams in big corporations.” But then he realized his team was drowning in spreadsheets, missed follow-ups, and lost quotes. Sound familiar? Yeah, I thought so. So he started looking into CRM systems tailored for manufacturers—and let me tell you, it changed everything.

See, manufacturing isn’t like selling software or retail. The sales cycles are longer, the relationships are deeper, and there are way more moving parts. You’ve got engineering teams, production schedules, supply chain logistics—all of which need to sync up with what the customer wants. A generic CRM just doesn’t cut it. It’s like trying to fix a gearbox with a hammer. Sure, you might make progress, but it’s messy and inefficient.

That’s why specialized Manufacturing CRM solutions exist. They’re designed to handle things like complex quoting, project timelines, custom configurations, and even post-sale service. Imagine being able to track a customer request from initial inquiry all the way through design, production, delivery, and support—without switching between five different tools. Sounds nice, right?

And here’s something people don’t always realize: CRM in manufacturing isn’t just for salespeople. Engineers use it. Project managers live in it. Even customer service reps rely on it. When everyone has access to the same real-time data, things start moving smoother. No more “I thought you sent that drawing,” or “Wait, did they approve the change order?” That kind of miscommunication? Gone.

Let me give you an example. There’s this company that makes custom industrial ovens. Before they adopted a proper Manufacturing CRM, their quoting process took over a week. Why? Because sales had to email engineering, wait for specs, send them to pricing, get approvals, and then finally draft a quote. By the time it reached the customer, half of them had already gone with someone else.

After implementing a CRM built for manufacturers, they automated most of that workflow. Sales enters the basic requirements, the system pulls in standard pricing and engineering templates, and within hours—not days—they can generate a preliminary quote. And if changes are needed? No problem. Everything is tracked, version-controlled, and visible to everyone involved.

It’s not magic. It’s just smart design. These CRMs understand that manufacturing workflows aren’t linear. They’re cyclical, collaborative, and often unpredictable. So the software adapts instead of forcing you to adapt to it.

Another thing I love? Integration. Most modern Manufacturing CRM platforms play nicely with ERP, PLM, and accounting systems. That means when a quote turns into an order, it flows straight into production planning without manual re-entry. Fewer errors, faster turnaround, happier customers.

And let’s talk about data—because wow, there’s a lot of it in manufacturing. Every interaction, every revision, every delivery note. Without a good CRM, that data is scattered across emails, file servers, sticky notes (yes, really). But when it’s all centralized, suddenly you can spot trends. Like noticing that certain industries respond better to specific messaging, or that one sales rep consistently closes deals faster because of how they manage follow-ups.

One manufacturer told me, “We used to make decisions based on gut feeling. Now we actually have numbers to back things up.” That shift—from intuition to insight—is huge. It helps with forecasting, resource planning, even hiring.

But look, adopting a new CRM isn’t always smooth sailing. I’ve heard stories. Teams resist change. People say, “I’ve been doing it this way for 20 years.” Totally valid. Change is hard. That’s why the best implementations start small. Maybe just the sales team uses it at first. Then customer service joins. Then engineering. One step at a time.

And training? Super important. Not everyone’s tech-savvy. Some folks still print out emails to read them. So you’ve got to meet people where they are. Show them how this tool actually makes their job easier—not adds another layer of complexity.

Customization is another big factor. No two manufacturers work exactly the same way. Your processes are unique. Your terminology, your approval chains, your product configurations. A good Manufacturing CRM lets you tailor the system to fit your business—not the other way around.

I remember visiting a plant where they make conveyor systems. Their CRM was customized to include things like site survey checklists, safety compliance tags, and integration with their CAD software. When a customer approved a design, the CRM automatically triggered the next steps in production. It wasn’t just a database—it was part of their operational nervous system.

And mobile access? Can’t forget that. Factory floors aren’t always near desks. Supervisors walk the floor, engineers visit client sites, sales reps travel constantly. Having a CRM that works on tablets and phones means updates happen in real time. No more waiting until Monday to log a Friday meeting.

Security matters too. We’re talking about sensitive customer data, proprietary designs, pricing models. A solid Manufacturing CRM comes with role-based permissions, audit trails, and encryption. You don’t want just anyone seeing that confidential quote for a defense contractor, right?

Now, cost is always a concern. I get it. Small and mid-sized manufacturers don’t have endless budgets. But here’s the thing: the ROI on a good CRM can be massive. Faster sales cycles, fewer lost opportunities, improved customer retention. One company I spoke with reduced their quote-to-cash time by 40%. That’s cash coming in faster. That pays for a lot of software.

Cloud-based options have made this even more accessible. No need for expensive servers or IT teams to maintain them. Subscribe, set up, go. Updates happen automatically. Scalable as you grow. Perfect for companies that want to move fast without heavy upfront investment.

And support? Crucial. You don’t want to be stuck figuring out a bug during a critical client negotiation. The best CRM providers offer responsive support, training resources, and even consulting to help you get the most out of the system.

Let’s not overlook customer experience. In manufacturing, trust is everything. If you deliver on time, communicate clearly, and solve problems quickly, customers stick with you for years. A CRM helps you do all that by keeping promises visible, deadlines tracked, and communication logged.

Think about it: when a customer calls asking about their order status, instead of saying, “Let me check with production,” you can pull up the exact timeline, see any delays, and explain what’s happening. That builds confidence. That’s professionalism.

Plus, upselling and cross-selling become way easier. The CRM shows you what a customer bought last year, when they’re due for maintenance, or if they’re in an industry that’s recently adopted a new technology. Suddenly, your outreach feels helpful—not pushy.

One thing I’ve noticed: manufacturers who use CRM well tend to have a culture of collaboration. Sales talks to engineering. Production shares feedback with customer service. Everyone’s aligned because they’re working from the same playbook. That kind of unity? It shows in the results.

And hey, it’s not just about today. These systems collect data over time. So when leadership wants to analyze performance, expand into new markets, or improve customer satisfaction, they’ve got real insights to guide them.

Look, I’m not saying a CRM will fix every problem. Bad management, poor quality, unreliable delivery—no software can save you from those. But if you’ve got the fundamentals down, a Manufacturing CRM can take you from good to great.

It’s like giving your team night-vision goggles in a dark warehouse. Suddenly, you can see where things are, where they’re going, and how to get them there faster.

So if you’re in manufacturing and still managing customer relationships with spreadsheets and sticky notes… maybe it’s time to look around. Talk to vendors. Ask peers what they use. Take a demo. See how it feels.

Because at the end of the day, your customers don’t care about your internal chaos. They care about whether you understand their needs, respond quickly, and deliver what you promised. A good Manufacturing CRM helps you do all three—consistently.

And honestly? That’s the kind of reputation that wins contracts, keeps clients for life, and grows businesses sustainably.

Q: What makes a Manufacturing CRM different from a regular CRM?

A: Great question. Regular CRMs are built for simpler sales cycles—like selling subscriptions or services. Manufacturing CRMs handle complex workflows: custom quoting, engineering collaboration, production tracking, and long-term service plans. They’re built for industries where every sale is a project, not just a transaction.

Q: Do I need technical skills to use a Manufacturing CRM?

Not really. Most modern systems are designed to be user-friendly. Sure, there’s a learning curve, but vendors usually offer training and support. Think of it like learning a new phone—awkward at first, then second nature.

Q: Can a small manufacturer benefit from this?

Absolutely. In fact, smaller companies often see the biggest improvements because they’re usually juggling more roles with fewer people. A CRM helps them stay organized and scale without adding headcount.

Q: How long does it take to implement?

It varies. A simple setup might take a few weeks. A full integration with ERP and other systems could take a few months. But many companies start seeing benefits within the first 30 days—especially in sales efficiency.

Q: Is my data safe in the cloud?

Yes, especially with reputable providers. They use encryption, secure data centers, and strict access controls. In many cases, your data is safer in the cloud than on a local server that could fail or get hacked.

Q: Can I customize the CRM to match my workflow?

Definitely. One of the biggest advantages is customization. You can tailor fields, dashboards, workflows, and reports to match how your team actually works—not force your team to change for the software.

Q: Will my team actually use it?

That depends on buy-in and ease of use. Involve your team early, show them how it reduces their workload, and provide training. Start with key features, then expand. When people see it helping them, adoption follows.

Relevant information:

Significantly enhance your business operational efficiency. Try the Wukong CRM system for free now.

AI CRM system.